Die FAQ-Einträge sind nur auf Englisch verfügbar.

Incomplete transmission of application data can lead to corrupted data in the iLCD panel's flash memory. To re-establish communication with iLCD Manager XE, the flash has to be erased completely by following these steps:

- Connect iLCD to interface/evaluation board (not powered)

- Close the jumper marked "Erase" on the interface/evaluation board

- Power up iLCD

- Verify "Flash erased!" being displayed on the iLCD

- Power down

- Remove "Erase" jumper

Note that in consequence of this procedure, all user-data stored in the iLCD panel's memory will be lost! If this approach doesn't lead to success, please use the contact form for a request for repair.

As you can store any fonts into the iLCD you want to have, it's up to you which character range you select to be used. Foreign characters like "äöü" are located in the second half of a code page (that means their ASCII code is higher than 128 decimal / 80 hex). When adding a font in iLCD Manager XE, the "Last Char" field in the "Convert Windows Font" dialog has to be set accordingly (e.g. 255 decimal).

After storing the modified flash data into the iLCD panel, the character range you've selected for converting can be displayed.

Decimal 170 is equal to hex AA which is the command introducer character ("\i"). When you want to send data containing this special byte value you must quote this character (that means sending it twice). When editing commands in iLCD Manager XE, quoting is done automatically (verify by checking the Hex representation).

Have a closer look at the iLCD Command Set specification, chapter "Syntax Used in Setup Program" to learn about how to send data to an iLCD panel.

First of all, please read the chapter "The Concept of iLCD's Touch Fields" in the iLCD Command Set specification.

If you still do not understand how touchfields work, try loading the "Touch Sample" or the "Simple Touch Field Demo" from the "New" section on iLCD Manager XE's "File" page. Then go to the "Macros" page and have a look to the macros used to make the touchfield work.

For migrating an application to an iLCD with a different display resolution, some scaling commands are available in the command set. By adding only four lines, the entire application can be adapted to fit the new screen.

When switching from monochrome to a color iLCD, the black and white graphics, texts and forms can be colored easily by setting foreground and background color to desired values.

For further information about porting applications, refer to the Migration Application Note.

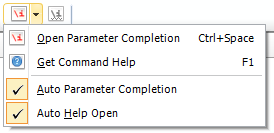

The features "Auto Help Open" and "Auto Parameter Completion" are enabled by default.

"Auto Help Open" automatically shows the command description of the focused command which causes a short change of the focus to the help file. When iLCD Manager XE and the help file are overlapping, this leads to a "flashing" effect. Arrange the two windows next to each other to benefit from this feature or disable it in the "iLCD Commands" submenu. When disabled, the description of the focused command can be opened by pressing F1.

"Auto Parameter Completion" opens the parameter completion form after a few seconds when an incomplete command is focused. When this feature is disabled, the parameter completion form can be manually opened by clicking the "iLCD Commands" button or Ctrl+Space.

In nearly 100% of all cases the touchscreen is simply disabled by accident. Please carry out the steps mentioned below. If the touchscreen still does not work afterwards, please get in contact with demmel products and ask for details about returning iLCDs for repair.

Please load your favorite *.lcdp-flash flash file or create a new one on the "File" page of your iLCD Manager XE, then go to the "Settings" page.

Ensure that the items marked in red in the screenshot are enabled.

If you are setting up a monochrome iLCD panel, the section "LCD Display" may be enabled. If this is true, take care to select the appropriate controller and width/height setting, otherwise the iLCD panel will not work properly anymore after writing the flash data!

Write the project to your iLCD with the "Write Project to iLCD" button in the Quick Access Toolbar or [Ctrl+W] .

After this your touchscreen should work as expected. You may re-calibrate it by sending the "Calibrate Touchscreen" (\iTC) command on the "Device" page and touching the crosshair positions on the touchscreen as desired.

You can test the calibration via the command "Verify Touchscreen Calibration" (\iTV) to ensure the touchscreen is working properly.

If the X/Y direction is swapped, check/uncheck the "Swap X/Y" checkbox on the "Edit Setup Data" screen and write data to the flash again. When doing so, a re-calibrating of the touchscreen must be done.

If this approach doesn't lead to success, please use the contact form for a request for repair.

If you are designing your application hardware that is interconnected to your iLCD by means of a flat cable, you eventually want to know which FFC connectors to use or which ones we deploy.

We use a connector type with the following attributes:

- Contact Plating: Tin or Gold

- Contact Position: Top

- Contact Termination: Surface Mount Right Angle

- Contact Termination Type: Surface Mount

- FFC/FPC Thickness: 0.3mm

- Gender: Plug

- No. of Contacts: 20 / 24

- No. of Rows: 1

- Pitch Spacing: 1mm

Examples for 20-pin / 24-pin connectors are Molex part no. 52207-2060 / 52207-2460 or TE Connectivity / AMP part no. 2-84953-0 / 2-84953-4.

The iLCD Manager XE runs on Windows XP, Windows Vista, Windows 7 and Windows 8.x.

We recommend

- A processor with at least 1 GHz

- 1 GB RAM

- 100 MB available disk memory

- Optionally access to the internet (for automatic updates)

We are a partner for the industry since many years, therefore we unterstand the need for a long term availability of parts. As a general principle, we use only displays which are long term available. If there is deployed a new one, then this is the main reason to release a succeeding iLCD model.

Should there be a part of our iLCD Panels go end-of-life, we look for an appropriate and at least equivalent replacement. Our main focus is to guarantee continuity in electrical characteristics, functionality and geometric dimensions.

iLCD Panels are regarded as components. There is a very wide variety of possible certifications and deployments. The certification of a device takes into account topics like grounding, power supply and housing/chassis - things we have no influence to. Therefore, it makes no sense to certify a component in advance. A device which includes an iLCD Panel may be certified indeed. Many of our customers have run through the process of, e.g., CE/ATEX/Ex certification already successfully, among others for medical devices or for devices on offshore drilling platforms.

demmel products gmbh declares compliance with the applicable RoHS directive and REACH regulation:

- Restriction of the use of certain Hazardous Substances (RoHS), directive 2011/65/EU

- Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), regulation EC No 1907/2006

We provide the declarations of conformity for each of our products upon request – please contact us.